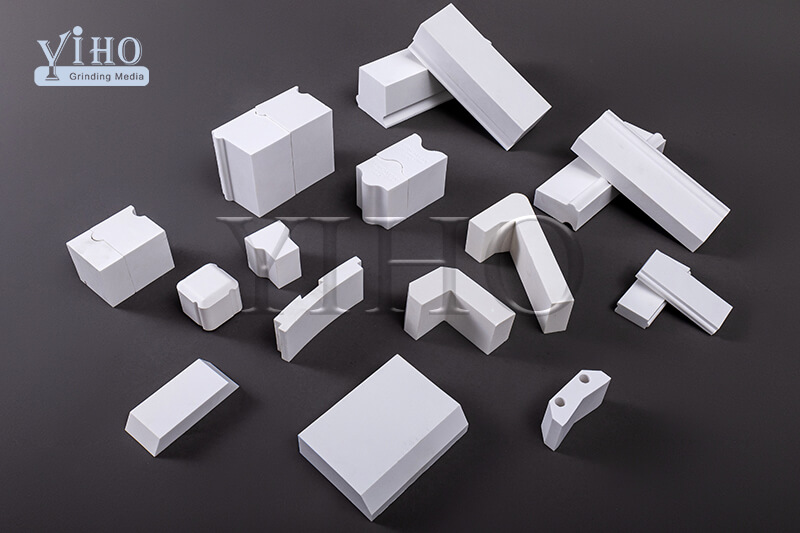

Machubu a ceramic ndi zigawo zooneka ngati zapadera

Kapangidwe kazinthu:

| Gulu | Mtengo wa HC90 | Mtengo wa HC92 | Mtengo wa HC95 | Mtengo wa HCT95 | HC99 | HC-ZTA | ZrO2 |

| Al2O3 | ≥90% | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% | / |

| ZrO2 | / | / | / | / | / | ≥21% | ≥95% |

| Kuchulukana | >3.50g/cm3 | >3.60g/cm3 | >3.65g/cm3 | >3.70g/cm3 | >3.83g/cm3 | >4.10g/cm3 | >5.90g/cm3 |

| Mtengo wa HV20 | ≥900 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 | ≥1100 |

| Rock Hardness HRA | ≥80 | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 | ≥88 |

| Kupindika Mphamvu MPa | ≥180 | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 | ≥800 |

| Mphamvu ya compression MPa | ≥970 | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 | / |

| Fracture Kulimbitsa KIc MPam 1/2 | ≥3.5 | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 | ≥7.0 |

| Valani Voliyumu | ≤0.28cm3 | ≤0.25cm3 | ≤0.20cm3 | ≤0.15cm3 | ≤0.10 cm3 | ≤0.05cm3 | ≤0.02cm3 |

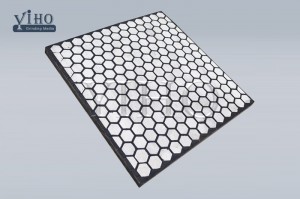

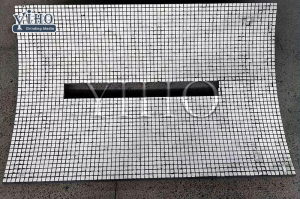

Zitsanzo Zogwiritsa Ntchito

Zindikirani: Titha kupanga alumina kuvala matailosi malinga ndi zomwe mukufuna.

Mawonekedwe

Kuuma kwakukulu

Kulimba kwa Rockwell kwa aluminiyamu apamwamba kwambiri mpaka HRA80-90 yomwe ili yachiwiri kwa diamondi ndipo imaposa chitsulo chosapanga dzimbiri chosavala.

Wabwino kuvala kukana

Kukana kuvala kwazitsulo za alumina za ceramic ndi nthawi 266 kuposa chitsulo cha manganese ndi 171.5 nthawi ya chitsulo chachitsulo cha chromium. Malinga ndi kafukufuku wathu & kutsatira kwa makasitomala, moyo wautumiki wa zipangizo ukhoza kupitirira nthawi 10 pansi pa zofanana. mikhalidwe yogwirira ntchito.

Kukana dzimbiri

Ma aluminiyamu apamwamba kwambiri ndi ma oxide okhala ndi ma cell okhazikika komanso osawonongeka ndi electrochemical, motero amatha kukana kukokoloka kwa asidi, alkali, njira zamchere ndi organic Solvents.

Thermostability

Kutentha kogwira ntchito kwazitsulo za aluminiyamu zapamwamba kumatha kufika 1400 ℃.

Kudzipaka bwino

High aluminiyamu zadothi ndi katundu kudzikonda lubricity ndi inadhesion, roughness ndi 1/6 yekha ndi mipope zitsulo motero zochepa otaya Kukana.

Kulemera kopepuka

Kachulukidwe ka aluminiyamu wapamwamba kwambiri ndi pafupifupi 3.6g/cm3, yomwe ndi theka la chitsulo, motero n'zosavuta kumanga ndi kukhazikitsa.

Valani mayankho omwe timapereka

Iyi ndi njira yovuta.Mainjiniya athu amamvetsetsa zovuta zovala ndikulongosola

mayankho kuti akwaniritse malo anu ogwirira ntchito.Katundu wa zinthu, kulolerana, kusalala, njira zophatikizira, ndi mtengo wazinthu zonse zimaganiziridwa mu kuvala s.

Mapulogalamu

• Ma chutes/Hoppers

• Mitundu ya Cones

• Olekanitsa Mphepo yamkuntho

• Zigongono

• Nyumba za Fan & Blades

• Lined Piping

• Nozzles

• Valani mapanelo

Misika

• Mphamvu Zopangira Malasha

• Kugwiritsa Ntchito Zinthu Zowononga

• Chemical Processing

• Kukonza Chakudya

• Kupanga Chitsulo/Chitsulo

• Kukonza Mchere

• Kutumiza Ufa/Zolimba Zambiri

• Kupanga Zamkati & Mapepala

• Kupuntha & Kupera