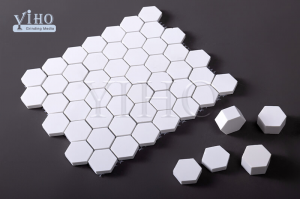

Ceramic kuvala mbale kwa aukali abrasion

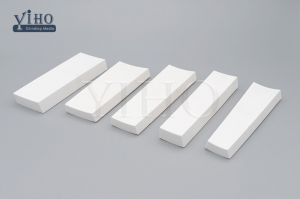

Valani mbale za malo ovuta

Ceramic kuvala mbale ali kwambiri kukana mawotchi abrasion ndi kukokoloka.Amagwiritsidwa ntchito mwanzeru ngati zida zomangira m'matupi otayira magalimoto ndi mabwato omwe amanyamula ndikutsitsa miyala ndi miyala yofukulidwa, pogwira zitsulo zolemera zachitsulo komanso ntchito yowononga komwe konkriti yokhala ndi zitsulo zolimbikitsira imatulutsidwa pabedi lathyathyathya.

M'munsi phokoso mlingo

Zida za ceramic za mbalezo zimayikidwa muzitsulo zachitsulo kapena zowonongeka mu rabala, zomwe zimawonjezera kukana kukhudzidwa ndi kuchepetsa phokoso la phokoso chifukwa cha kugwedezeka kwa mphira.Zitha kutsekedwa kapena kumangirizidwa mwachindunji pamwamba pa mbale yovala.

Kupanga motsatira ndondomeko

Yiho nthawi zonse amapereka njira yabwinoko pomwe mbale zathu za ceramic zimapangidwa molingana ndi zomwe makasitomala amafuna.Poganizira, mwa zina, kugwiritsa ntchito ndi kuyenda kwa zinthu, mtundu wa ceramic, miyeso ndi makulidwe, ndikuyika kapena popanda kuyika mphira, ndi zina zambiri.

Zida za Ceramic: Silicon Carbide

Silicon Carbide (SiC)

Silicon carbide imapangidwa m'njira ziwiri, kugwirizanitsa ndi sintering.Njira iliyonse yopangira imakhudza kwambiri kumapeto kwa microstructure.

Rection Bonded SiC imapangidwa ndikulowetsa zosakaniza zopangidwa ndi zosakaniza za SiC ndi kaboni ndi silicon yamadzimadzi.Silicon imakhudzidwa ndi carbon kupanga SiC yambiri yomwe imagwirizanitsa tinthu tambiri ta SiC.

Sintered SiC imapangidwa kuchokera ku ufa woyera wa SiC wokhala ndi zida zopanda oxide sintering.Njira zanthawi zonse zopangira ceramic zimagwiritsidwa ntchito ndipo zinthuzo zimayikidwa mumlengalenga mopanda kutentha mpaka 2000ºC kapena kupitilira apo.

Mitundu yonse iwiri ya silicon carbide (SiC) imavalidwa kwambiri yokhala ndi zida zabwino zamakina, kuphatikiza kulimba kwa kutentha kwambiri komanso kukana kugwedezeka kwamafuta.Mainjiniya athu amakhalapo nthawi zonse kuti akupatseni upangiri wabwino pazamphamvu ndi zofooka za ceramic iliyonse pazosowa zanu.

Makhalidwe abwino a silicon carbide ndi awa:

• Kutsika kochepa

• Mphamvu zapamwamba

• Kutentha kwabwino kwamphamvu (zogwirizana)

• Oxidation resistance (machitidwe amagwirizana)

• Kukana kwabwino kwa kutentha kwa kutentha

• Kuuma kwakukulu ndi kukana kuvala

• Kukana kwabwino kwa mankhwala

• Kukula kwamafuta ochepa komanso kutulutsa kwapamwamba kwamafuta

Zomwe zimagwiritsidwa ntchito ndi silicon carbide zimaphatikizapo:

• Zida zokhazikika komanso zosuntha za turbine

• Zisindikizo, mayendedwe, mapampu vanes

• Zigawo za valve za mpira

• Valani mbale

• Mipando ya mu uvuni

• Zosintha kutentha

• Zida zopangira makina opangira ma semiconductor

Kuti mumve zambiri za silicon carbide yathu komanso momwe ingagwiritsire ntchito malonda anu, lemberani lero